Ramsey Equipment Replacements by Leveltec Engineering

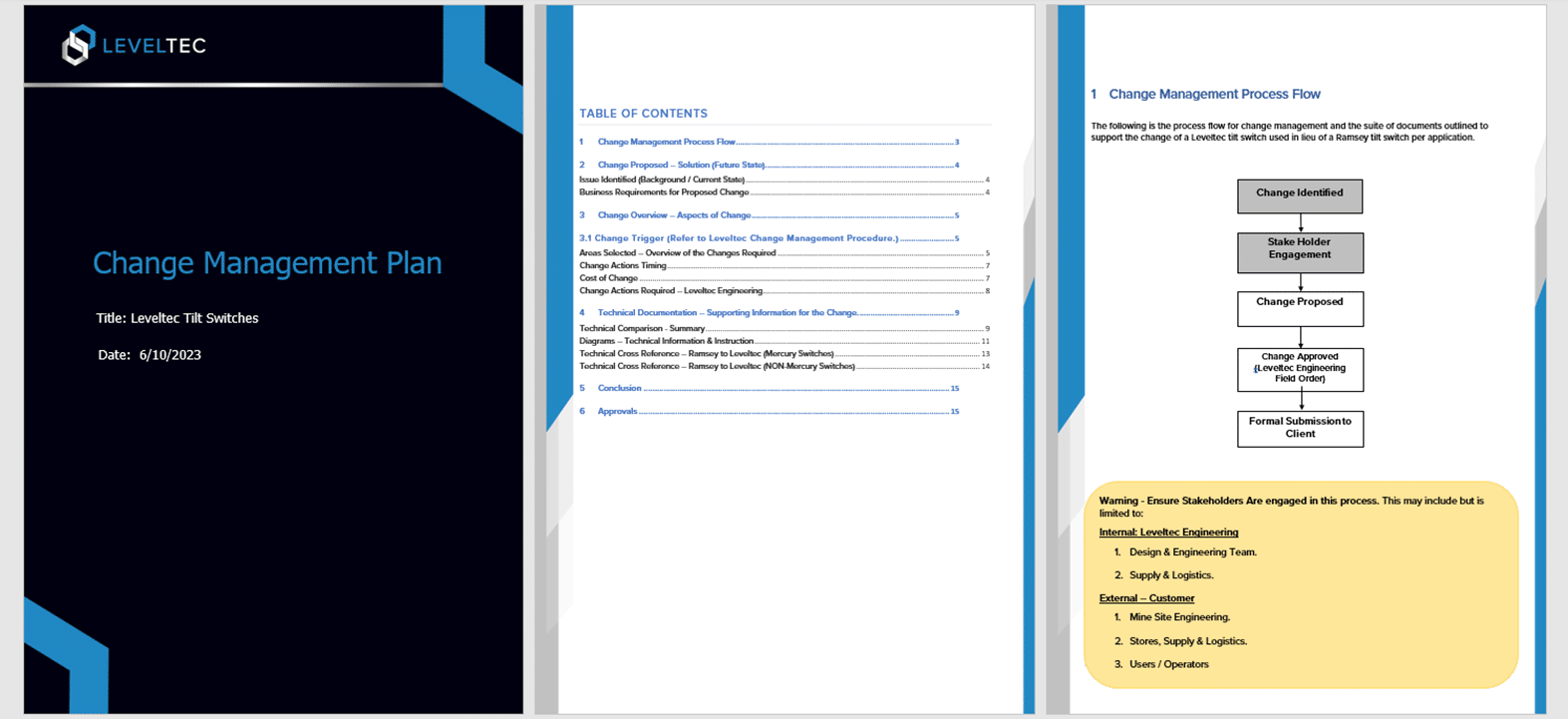

With discontinued products there becomes a challenge of change. What do we do, how do we do it and what do we actually need?

Here at Leveltec we have been manufacturing and distributing control devices for material handling monitoring applications for the past 40 years. Our tilt and temperature switches are Australian made and meet current Australian and New Zealand standards. They are designed to meet the specific need of level and thermal detection for bulk material handling applications, and offer increased reliability, performance and non-mercury solutions.

We offer mercury and non-mercury solutions for bulk material handling, fixed plant and moving plants, and bearing temperature monitoring. Sourcing your tilt and temperature switches from Leveltec means you benefit from high quality Australian-made products, quick turnaround on orders, the ability to bespoke solutions and the knowledge you are supporting the local manufacturing industry.

Here at Leveltec, our specialty is applications support when it comes to applying for change. Speak to our team about the replacement of your current Ramsey tilt switches and the management change that needs to take place, so all aspects of your business needs are addressed.

Contact Leveltec to upgrade your tilt switches

Where do I go from here?

You’re not alone… If this change affects multiple stake holders across multiple sites and you want a way to clearly communicate it, speak to us about the change management plan we have developed to document this change and get you up and running in no time.

Ready to Replace now?

Here is a summary table of comparable models and options for increased reliability

Mercury Tilt Switches

| Ramsey Model (Mercury Type) | Type | Leveltec Equivalent Model | Leveltec Spec Document Reference Download File via Link Below |

Reliability Increase |

|---|---|---|---|---|

| 20-39 | Mercury – Cast Steel, Heavy Duty 15407 Tilt, Switch 20-39 4.5m 15408 Tilt, Switch 20-39 7.6m |

LP04-S2-CH/6/6 | File link: HERE | ADD HD after / to install HD braided Cables |

| 20-30 | Mercury – Stainless Steel 15410 Tilt, Switch 20-30-SS |

LP04-S2-SS/6 | File link: HERE | ADD HD after / to install HD braided Cables |

| 20-31 | Mercury – Plastic (Lightweight) | LP05-S2-PVC/6 | File link: HERE | ADD HD after / to install HD braided Cables |

| 20-44 | Mercury – 110-240VAC version 15431 Tilt, Switch 20-44 25 f cable |

LP04-S2-CH/HD6 | File link: HERE | |

| 15432 Tilt, Switch 20-44 SS f cable 110/240 V | LP04-S2-SS/HD6 | File link: HERE | ||

| 20-35A | Tilt Switch Controller | LTS-TS-Time Delay Controller | Contact us: HERE | Time delay control of Signal in the field. |

Non-Mercury Tilt Switches

| Ramsey Model (Non- Mercury Type) | Type | Leveltec Equivalent Model | Leveltec Spec Document Reference Download File via Link Below | Reliability Increase |

|---|---|---|---|---|

| 20-59-NM 21-59-NM (hazardous area) | Standard 1 in. Nickel Plated Cast Ductile Iron Probe | LP01-S2-CH/6 | File Link: HERE | Hydraulic Time damping provides stability in high vibration, wind, ore surges, and impacts. Direct connection to PLC. |

| 20-55-NM-P | 1 in. Light Weight | LP02-S2-PVC/6 | File Link: HERE | Hydraulic Time damping provides stability in high vibration, wind, ore surges, and impacts. Direct connection to PLC. |

| 20-54-NM-SS 21-54-NM-SS (hazardous area) | 1 in. Stainless Steel Probe | LP01-S2-SS/6 | File Link: HERE | Hydraulic Time damping provides stability in high vibration, wind, ore surges, and impacts. Direct connection to PLC. |

| 20-52-NM 21-52-NM (hazardous area) | 2 in. Heavy Weight Probe | LP01-S2-SS/6 | File Link: HERE | Hydraulic Time damping provides stability in high vibration, wind, ore surges, and impacts. Direct connection to PLC. |

| 20-35-NM-(F/DIN) | Field Mount Control (IP65/NEMA 4) DIN Mount Control (IP20/NEMA 1) | LEVELTEC SNAP ACTION TILT SWITCHES DO NOT REQUIRE ELECTRONIC CONTROLS TO OPERATE | Leveltec LP01 /02/ 03 units do not need a controller to stabilize the signal. The LTS-TS-TIME DELAY CONTROLLER can be used as required OR direct sensor connection to PLC. |

Leveltec Products

Do You Have Other End of Life Ramsey Equipment?

SiTec specialises in the design and manufacturing of safety and monitoring switches tailored for industrial conveyor technology. As a German manufacturer, they are dedicated to crafting resilient safety switches that cater to various industry sectors, ensuring the dependable security and monitoring of your conveyor belt systems.

SiTec’s switches are engineered to endure demanding environments, such as those encountered in the raw materials sector, including open ore mining and the iron and steel industry. Our products are not only robust but also synonymous with durability and exceptional quality. SiTec have a lot of bolt compatible replacements for all proline conveyor monitoring.

Contact Leveltec

Pull wire & belt misalignment switch – Discontinued

Continuous level indicator – Discontinued

| Thermo Fisher – Ramsey | EFD – Sitec | ||

|---|---|---|---|

| Switch type | Switch type | ||

| Pull rope switch | Pull rope switch | ||

| SPS | safety pull switch SPS housing aluminum (automatic reset) | ||

| SAS | Snap Action Switch SAS housing aluminum (manual reset) |

SNA SND SNE |

snap action switch, aluminum housing snap action switch plastic housing snap action switch stainless steel housing |

| TPS |

Limit switch Tripper position switch TPS housing aluminum |

PEA PED PEE |

Limit switch position switch aluminum housing position switch plastic housing position switch stainless steel housing |

| ROS |

Misalignment switch Run off switch ROS housing aluminum |

PSA PSD PSE |

Misalignment switch misalignment switch aluminum housing misalignment switch plastic housing misalignment switch stainless steel housing |

|

2E 4E |

Switching unit all switching types 2 changeover contacts 6A/250VAC, 10A/ 30VDC 4 changeover contacts 6A/250VAC, 10A/ 30VDC |

1-3 NO 1-3 NC 1-4 SPDT |

Switching unit SN 1-3 NO contacts in silver or gold coating 1-3 NC contacts in silver or gold coating Switching unit PE +PS 1-4 changeover contacts silver coating |

|

1 3 |

Hazardous area approvals 1 cCSAus nonhazardous 3 cCSAus hazardous area rated for Class II Div 1+2 Groups E,F,G |

Hazardous area approvals DIN EN 60947-5-1, DIN EN 60947-5-5, DIN EN 620, DIN ISO 13850, EN IEC 60079-0, EN 60079-31 EX Versions for zone 21 and 22 available |

|

|

4 4x NP |

Finish / NEMA Rating 4 Nema4 steel external components 4X NEMA 4x stainless steel external components NP nicel plates enclosure and stainless steel external components |

||

|

NPT MET |

Conduit openings 2 x NPT standard 3/4-14 NPT threads 2 x MET Metric M20 x 1,5 threads |

2 3 4 |

Conduit openings 2 openings M25 x 1,5 2 openings M20 x 1,5 4 openings M20 x 1,5 |

|

LT SW FR SR |

Light 24V, 120V or 240V Steady white Flashing red Steady red |

L1 L2 |

Light LED light red 230V LED light red 24V |

|

Temp Spacing Fixing points BUS Protection class |

Technical Data -40C to +85C Max 60cm 171mm by 100mm Optional addressable module IP 65 |

Temp Spacing Fixing points BUS Protection class |

Technical Data -40C to 70C Max 100mm 162mm by 54mm – adapter plate available Optional addressable module IP 67 |