Leveltec was approached to visit one our existing customer and provide a solution to a maintenance issue involving cables that supply power to crusher electric motors. The client experienced from time to time inconsistency with maintenance practices when the plugs had been disconnected which caused damage and moisture to the plugs from time to time. The maintenance involved mechanical handling of heavy cables and plugs so that they could be make room to roll the crushing unit out and change wear parts. On re commissioning of the plant, unplanned downtime sometimes occurred days after the maintenance due to poor connections or moisture which was unknown at the time of re install. All of these factors combined posed risk to safety and loss of income.

Project Objective

Review the current onsite environment and issues around cable plug damage, plant start-up downtime post-maintenance and requirement for extra resources to perform maintenance procedures.

Solution – What did we do and how did we do it:

Leveltec visited the client onsite to review and plan the best possible position for the cable carrier to minimise the infrastructure changes, cable routes and personal traffic. Working with the clients, we identified their cable requirements and matched the chain to suit with bending radius and mounting brackets.

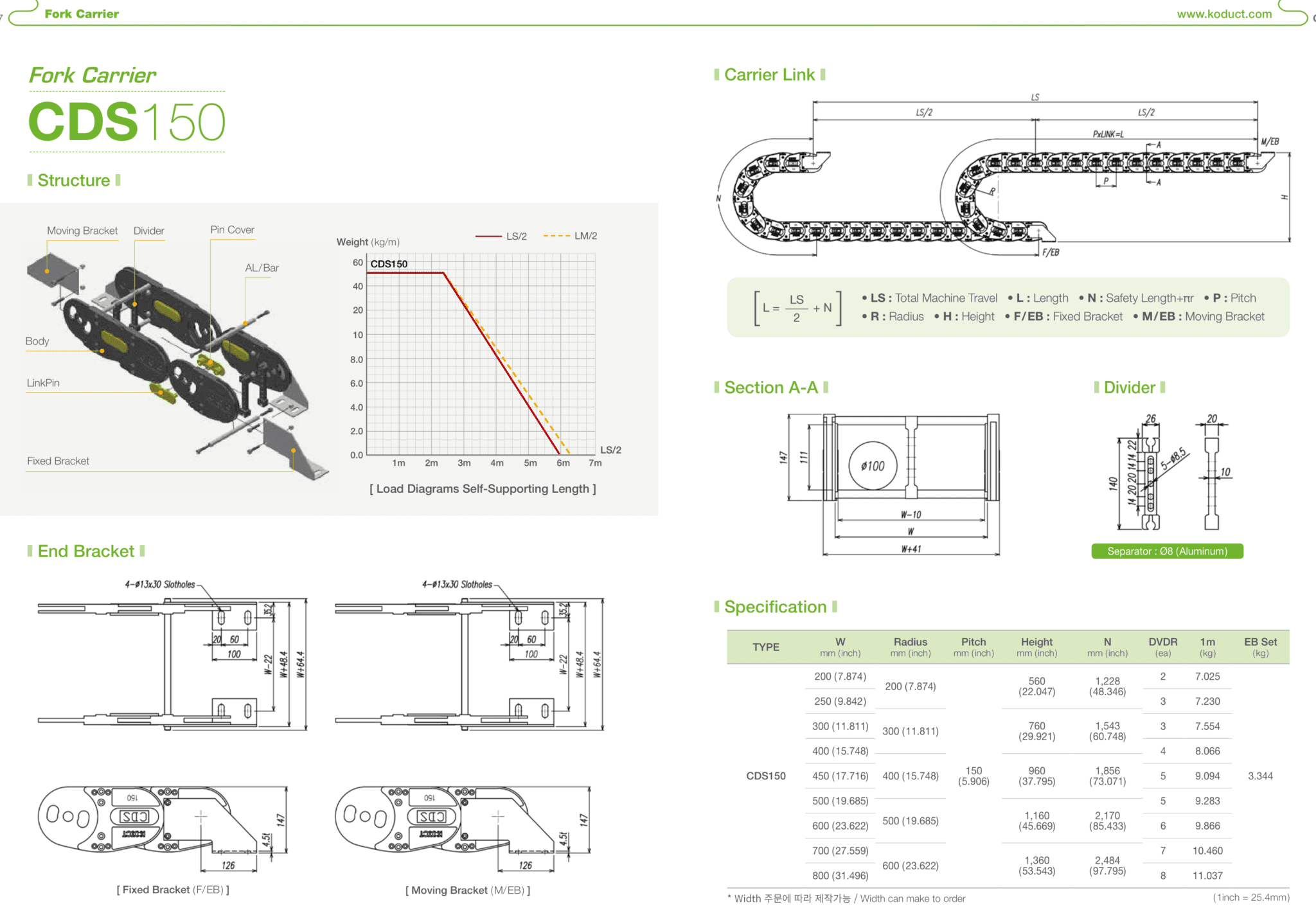

Working Closely with our partner Koduct, we quickly created a custom drawing and overlayed it to the mines existing structure before proceeding. With the CDS150 chain selected we got to work locally assembling the Body, link pins and special order stainless steel cross bars in 7.5 total. For ease when handling, we supplied the chains in 1m lengths and provided tooling / instructions to onsite contractors to help with the install. The removable cross bars and 1m lengths allowed the chain cable to installed onsite as per the clients request. Pre-assembled chains with cables are also asoptions for clients. The Installation of a cable carrier / energy chain eliminated the requirement for power and control plugs. By removing the plugs it also eliminated the requirement for manual handling risk and extra resources. Mechanical trades can now isolate the equipment and perform maintenance faster.

Technical Data

A durable solution of glass reinforced engineering plastics and stainless steel cross bars to suit the mining environment. The CDS150 fork carrier is suited to medium distance, high speeds and high load applications.

Conclusion

The overall objective of the project was completed and since installation has reduced the number of downtime events post maintenance, reduced the number of resources required to complete the task, Remove a manual handling risk and ultimately increased production uptime.

DOWNLOAD SHORT FORM GUIDE Download Case Study

Enter your details below to access the downloads.