Project Objective

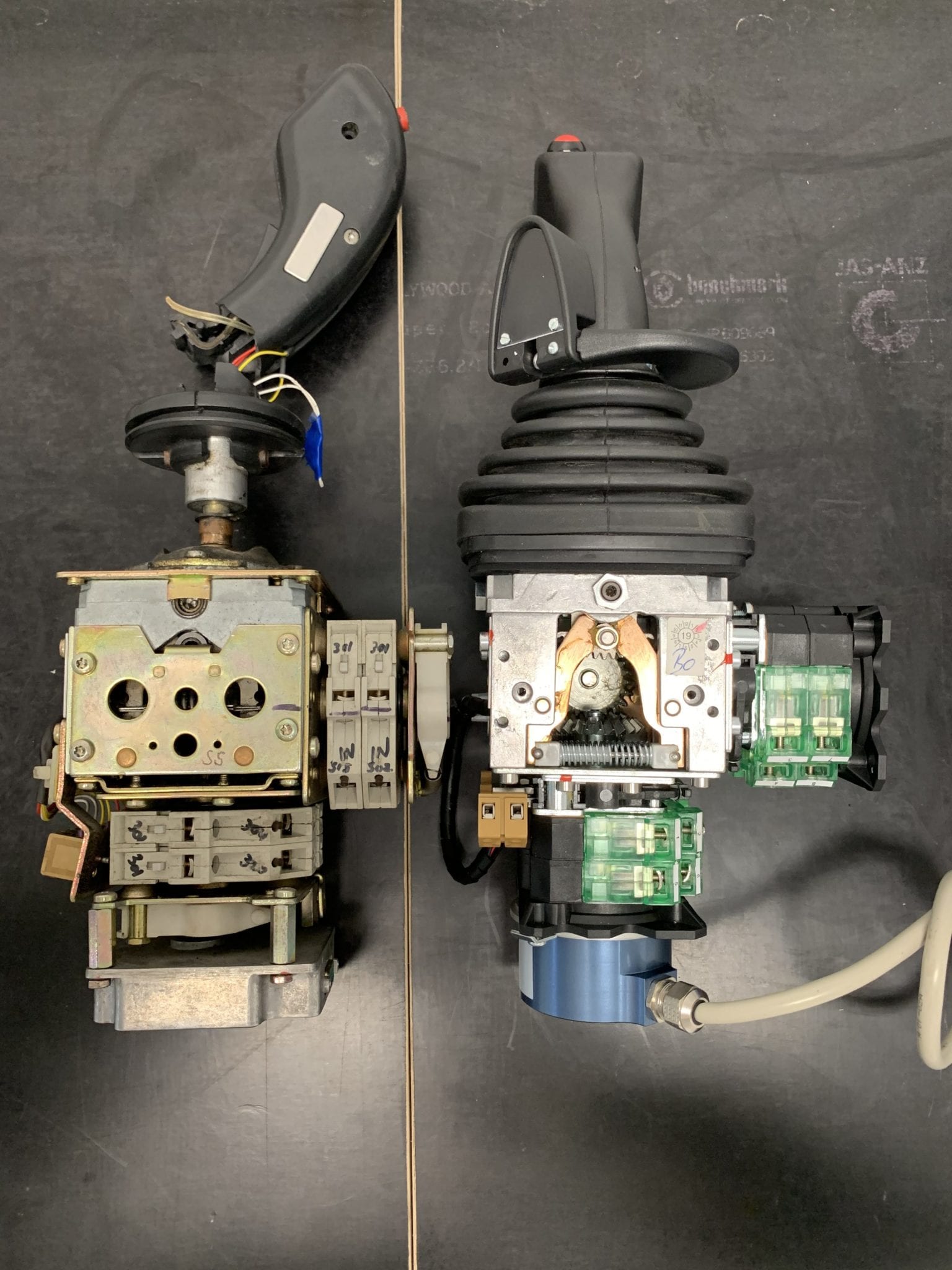

One of our long term coal ship loader clients in Queensland required another retrofit upgrade after successful integration of Spohn + Burkhardt joysticks a few year back. We needed to re-evaluate the needs of the clients of the clients to ensure the look, feel and fit still matched the environment. The change management process was accepted by operations and actioned again bringing another shiploader operator console for the Leveltec teams to service.

Solution

Our factory trained technicians locally assembled two new shipload joysticks for this ship loader operator console. The joysticks had to be configured to perform the operations in multiple directions and output both digital and analogue signals. The joysticks where fitted with upgraded IP65 rubber boots which greatly reducing the risk of electronic damage during cleaning or in the event of a spill. For increased comfort to the operators, a new palm rest was added to the handle assembly.

Technical Details

- Heavy duty metal drive block VNS0 series joystick controller

- Single and Multi-axis controllers

- Spring return to centre

- Handles with momentary push buttons and or Deadman switch (operator present switch)

- Digital contacts for direction

- Absolute encoder 4-20 mA for angular displacement reference

Conclusion

A successful retrofit by working with our customers to understand their real needs when it comes to reducing risk, increasing operator comfort and maintain their operational goals. The joysticks is one component of a very large moving wheel in a ship loading operator console. The client is now setup with an joystick that can be locally serviced and repaired for a number of years to come thus reducing their operational risk.