How to rapidly deploy multiple temperature measurement points across the plant?

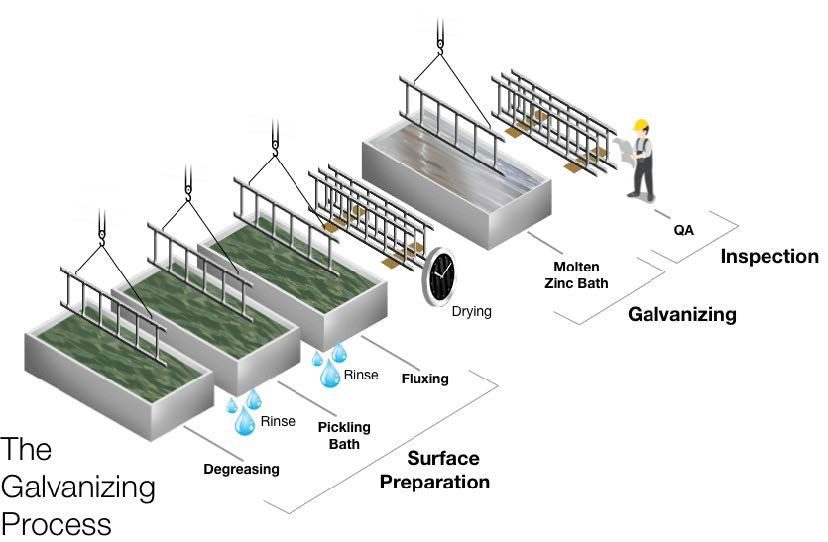

Process

Corrosion protection is achieved on metallic parts by hot dipping metal parts in liquid zinc (coating) at 450ºC. A process with multi-stage parts surface preparation, drying stage and galvanizing.

Objective

Monitor and easily data log the entire process temperatures in surface preparation, drying stage and zinc bath to ensure correct operation of equipment, compliance and quality.

Solution

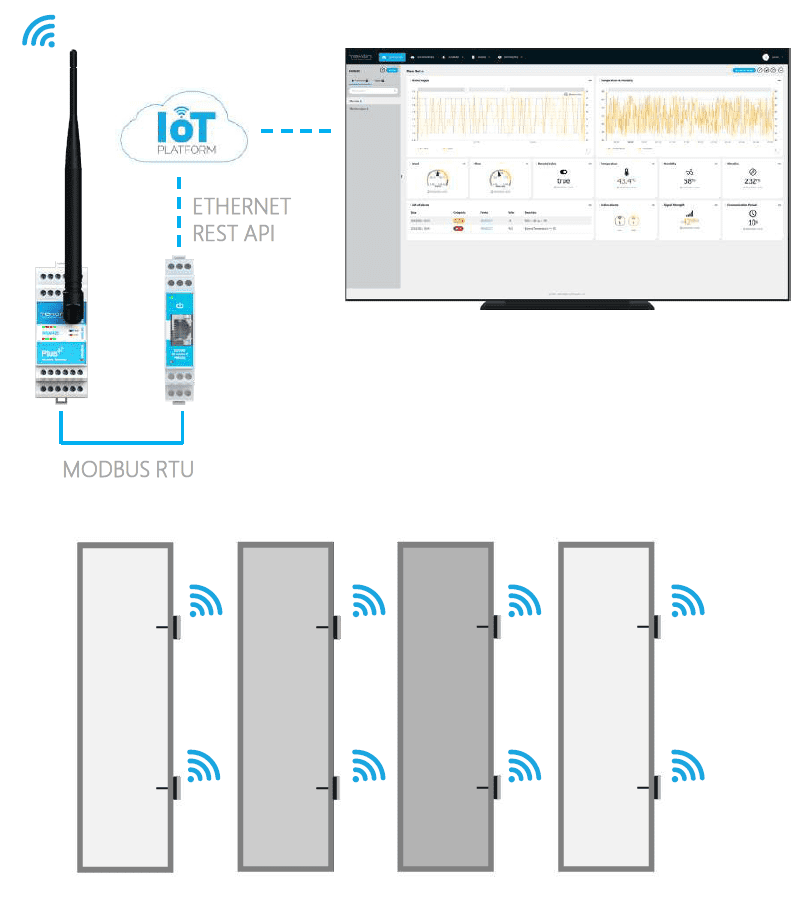

A wireless solution consisting of temperature probes, field enclosures installed close to the tanks and receiving gateway at a central control room.

PT100 RTD’s where installed at the process bath’s. Nearby the field enclosure was mounted and hard wired cables connected the probes. Reticulated power was available at each bath therefore each enclosure was fitted with a power supply to power the transmitters. Optional Battery units where available to be connected however as there was power available and the client wanted frequent sampling rates it was decided to have a powered system.

Technical Details

Thermocouples and cables matches to the clients requirements.

Temperature probes and cabinets with wireless transmitters and power supplies.

Temperature probes (Pt100 and TC)

(Installed by the client on each process point)

PLUS TWPH-1UT transmitters

(Directly connected to temperature probes)

Power supply

(To power wireless transmitters)

PLUS WGW420 + PIM101 + Tekon IoT Platform

(To receive wireless data and send to TIP installed on a local PC)

Conclusion

With the use of Tekon IoT ready hardware and software this client was able to take advantage of a cost effective and lightweight alternative to traditional automation systems.

In house design and pre assembled solutions made for a fast and easy deployment only taking 1 day to deploy 24 measuring points around the plant.

Once commissioned the client was sampling data in real time via the locally installed Tekon IoT platform where the could trend data, produce automated reports and send email/SMS notification for transmitters alerts.

The greatest advantage is the steps the client has taken in the digitalisation journey. The scale of the investment is tailored to your current needs meaning you only pay for what you actually use. When the time comes for more monitoring then this system will be able to connect up to 55 field transmitters and 220 temperature sensors without a requirement for extra gateways or IoT modules.

Want to learn more about the wireless universal transmitters?

Enter your details below to access the downloads.